How hot does a crematory furnace get? This question delves into the fascinating realm of cremation technology, where intense heat plays a crucial role in transforming human remains into ashes. Embarking on this journey, we will explore the temperature range, fuel sources, design, and environmental considerations that shape the operation of these specialized furnaces.

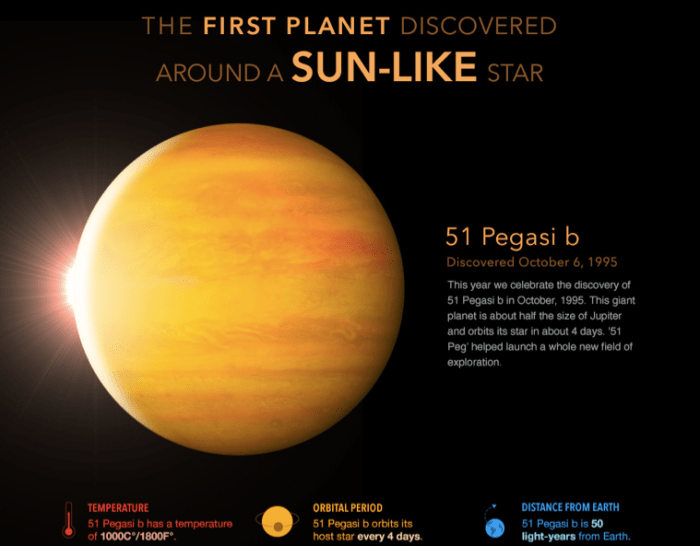

Crematory furnaces operate at exceptionally high temperatures, typically ranging from 1400 to 1800 degrees Fahrenheit (760 to 982 degrees Celsius). These extreme temperatures ensure the complete incineration of the body, reducing it to bone fragments that are further processed into ashes.

Temperature Range

Crematory furnaces operate within a specific temperature range to ensure complete and efficient cremation.

The typical temperature range for a crematory furnace is between 1400 and 1800 degrees Fahrenheit (760 to 982 degrees Celsius). This range provides the necessary heat to reduce the body to bone fragments and ash.

Factors Influencing Temperature Variations

Several factors can influence the temperature variations within a crematory furnace, including:

- Type of furnace:Different types of crematory furnaces, such as retort or flame-based furnaces, may have slightly different temperature ranges.

- Fuel type:The type of fuel used, such as natural gas or propane, can affect the temperature output.

- Cremation chamber size:Larger cremation chambers may require higher temperatures to maintain the same level of efficiency.

- Body weight and composition:The weight and composition of the body being cremated can also influence the temperature required for complete cremation.

Fuel Sources and Combustion: How Hot Does A Crematory Furnace Get

Crematory furnaces utilize various fuel sources to generate the intense heat required for the cremation process. These fuel sources can be classified into two primary categories: gaseous and liquid fuels.

Gaseous fuels, such as natural gas and propane, are commonly used in crematory furnaces due to their efficient combustion and relatively low environmental impact. Natural gas is a clean-burning fuel that produces minimal emissions, while propane offers higher energy density and is suitable for areas with limited access to natural gas infrastructure.

Liquid fuels, such as fuel oil and diesel, are also employed in crematory furnaces. Fuel oil is a heavy, viscous fuel that requires preheating before combustion, while diesel is a lighter, more refined fuel that ignites more readily. Liquid fuels generally have higher energy density than gaseous fuels, but they also produce more emissions and require proper handling and storage.

Combustion Process

The combustion process in a crematory furnace involves the rapid reaction of fuel with oxygen to generate heat. This reaction occurs in a controlled environment within the furnace’s combustion chamber. The fuel is introduced into the chamber and mixed with air, creating a fuel-air mixture.

An ignition source, such as a spark or flame, initiates the combustion process, causing the fuel-air mixture to ignite and release a significant amount of heat.

Efficiency and Environmental Impact

The efficiency of a crematory furnace’s fuel system is crucial for optimizing energy consumption and minimizing operating costs. Factors such as proper burner design, combustion chamber geometry, and temperature control contribute to the overall efficiency of the furnace. Additionally, the choice of fuel can impact efficiency and environmental impact.

Gaseous fuels generally offer higher efficiency and lower emissions compared to liquid fuels, making them a more environmentally friendly option.

Furnace Design and Construction

Crematory furnaces are meticulously designed and constructed to ensure efficient and safe operation. They consist of a primary combustion chamber and an afterburner, each serving distinct functions in the cremation process.

Materials and Thermal Properties

The furnace’s primary chamber is constructed from refractory materials, such as ceramic fiber or firebrick, which possess excellent thermal insulation properties. These materials can withstand extremely high temperatures, preventing heat loss and ensuring efficient combustion.

Safety Features and Regulatory Requirements

Crematory furnaces are equipped with various safety features to minimize risks. These include temperature sensors to monitor and regulate the combustion process, as well as automatic shut-off mechanisms to prevent overheating. Additionally, they adhere to strict regulatory requirements set forth by governing bodies to ensure compliance with environmental and safety standards.

Temperature Control and Monitoring

Precise temperature regulation is crucial in crematory furnaces to ensure complete and efficient cremation while minimizing emissions and maintaining safety. Advanced instrumentation and control systems are employed to monitor and adjust the furnace temperature accurately.

Instrumentation, How hot does a crematory furnace get

- Thermocouples:High-temperature thermocouples are placed at strategic locations within the furnace chamber to measure the temperature in real-time.

- Control Panel:A centralized control panel displays temperature readings, allows for manual adjustments, and triggers alarms in case of deviations.

- Programmable Logic Controller (PLC):The PLC is a computer-based system that automates the temperature control process, adjusting fuel flow and combustion parameters based on the desired temperature profile.

Temperature Regulation

The PLC monitors the temperature readings from the thermocouples and compares them to the pre-set temperature profile. It then adjusts the fuel flow and combustion conditions to maintain the desired temperature. This closed-loop control system ensures precise and stable temperature regulation throughout the cremation process.

Importance of Temperature Regulation

- Complete Cremation:Precise temperature control ensures that the body is completely cremated, leaving only sterile remains.

- Emissions Control:Proper temperature regulation minimizes the production of harmful emissions by ensuring efficient combustion and reducing the formation of pollutants.

- Safety:Accurate temperature monitoring prevents overheating and potential damage to the furnace and its components.

Environmental Considerations

Crematories have an environmental impact due to the emissions released during the cremation process. These emissions include particulate matter, volatile organic compounds (VOCs), and greenhouse gases such as carbon dioxide (CO2).

To minimize pollution, crematories are subject to regulations and must implement technologies that reduce emissions. These technologies include:

Emission Control Systems

- Electrostatic precipitators (ESPs):Remove particulate matter from the exhaust gas.

- Scrubbers:Remove acid gases and VOCs from the exhaust gas.

- Catalytic converters:Reduce the levels of CO and VOCs in the exhaust gas.

Crematories and Sustainable Death Care

Crematories play a role in sustainable death care practices by reducing the environmental impact of traditional burials. Cremation requires less land than burial, and it does not contribute to the release of harmful chemicals into the soil or groundwater.

In addition, crematories can use renewable energy sources, such as solar or wind power, to reduce their carbon footprint.

Historical Context and Cultural Variations

Cremation has been practiced for centuries across various cultures, with the earliest evidence dating back to the Neolithic period. The technology of crematory furnaces has evolved significantly over time, influenced by cultural beliefs and technological advancements.In ancient Greece and Rome, cremation was a common practice, and the design of crematory furnaces reflected the prevailing beliefs.

Greek furnaces were typically large, open-air structures, while Roman furnaces were more enclosed and designed to maximize heat retention.

Cultural Variations

Cultural variations in cremation practices have had a significant impact on furnace design. In some cultures, such as Hinduism, cremation is seen as a sacred ritual, and the furnace is often designed to be ornate and symbolic. In other cultures, cremation is viewed as a more practical method of body disposal, and the furnace is designed to be efficient and cost-effective.

Temperature Significance

The temperature at which cremation is performed varies depending on cultural beliefs and the type of furnace used. In some cultures, a high temperature is considered necessary to ensure complete destruction of the body, while in others, a lower temperature is preferred to preserve certain bones or ashes.

Question Bank

What factors influence the temperature of a crematory furnace?

The temperature of a crematory furnace is influenced by factors such as the size and weight of the body, the type of casket or container used, and the efficiency of the furnace itself.

How is the temperature of a crematory furnace controlled?

The temperature of a crematory furnace is controlled using a combination of sensors, controllers, and actuators. These systems work together to maintain the desired temperature throughout the cremation process.

What are the environmental considerations associated with crematory furnaces?

Crematory furnaces can emit pollutants such as particulate matter, carbon monoxide, and nitrogen oxides. However, modern crematories employ advanced pollution control technologies to minimize these emissions and comply with environmental regulations.